| CONVENTIONAL NDT EQUIPMENTS |

|

|

| |

|

|

| I. RT Equipments |

|

|

| |

|

|

| 1. Gamma Source Projector and Accessories - 660B/Delta 880 |

|

|

|

Applications: The Gamma source projectors are used for industrial applications of gamma radiography, mainly with Iridium-192, to inspect materials and structures in the density range of approximately 2.71g/§¨ through 8.53g/§¨. Low energy isotopes can be accommodated to permit radiography of materials and structures of thin sections of steel and low-density alloys.The 880 series exposure devices are also designed for use with low activity sources with highphoton energies for mass absorption (gamma scanning) studies of high-density materials upto 18.7g/§¨.

Original: Sentinel/USA

Quantity: 07 sets

|

|

|

| |

|

|

| 2. IRIS 10 Crawler X-RAY/X-RAY Head |

|

|

|

Application: It is intended for the X-Ray radiographic inspection of butt welds in pipelines measuring 12” to 60” diameter, which can be increased upon request

Original: IPSI/France

Quantity: 02 sets

|

|

|

| |

|

|

| 3. Automatic Film Processing Equipment – NDT M eco |

|

|

|

Application: The NDT M eco processor is the smaller version of the NDT Seco. Thiscompact film processor occupies a minimal amount of space in your darkroom. The NDTMeco is versatile, in the laboratory or transportable in a mobile site darkroom. It processessheet film as well as roll film up to any length. Specially designed for consumers of small and medium sized quantities of film. The ease of use and the problemfree maintenance make theNDT Meco an extremely user-friendly and reliable

processor

Original: GE Sensing & Inspection Technologies/Germany

Quantity: 03 sets |

|

|

| |

|

|

| 4. Film Dryer Machine – Structurix Dryer |

|

|

|

Appication: With the new Structurix Dryer, films dry more rapidly then in conventional drying cabinets. The drying process immediately starts with no warm- up time needed. Most water is removed from the film by means of squeegee rollers prior to the drying section. The film is thenhot air dried on both sides and collected in the adjustable film tray

Original: GE Sensing & Inspection Technologies/Germany

Quantity: 03 sets

|

|

|

| |

|

|

| 5. Industrial Film – FUJI X-ray Film |

|

|

|

Application: Fuji X-Ray Films is for non-destructive materials testing with fine grain and highcontrast. This film, of ASTM class 1 & 2, is especially suitable for test objects of medium tohigh density. This film ist can be used for testing with isotopes or X-rays and yields a highcontast

Original: FUJI/Japan

|

|

|

| |

|

|

| 6. Radiation Survey Meter – Monitor 4 |

|

|

|

Appication: New ergonomic design. The M4 and M4EC are compact, general

purpose survey meters capable of detecting alpha, beta, gamma, and x-rays over 3 selectable ranges. A red count light flashes and a beep sounds with each event detected. The Monitor4EC offers a more linear reading for gamma and x-rays (above 40 keV)

Original: S.E. Internaltional/USA

Quantity: 20 units |

|

|

| |

|

|

| II. UT/UTM Equipments |

|

|

| 1. Portable UT Flaw Detector - Sitescan D-10 |

|

|

|

Applications: The Sitescan D-10 uses a broad band amplifier compatible with a wide range of transducers whilst the D-20 model uses several narrow bands for improved performance. The “analogue feel” from the high quality broadband amplifier shows all the detail required to identify defect types such as holes or cracks, and sufficient resolution for identifying small signals. Typical applications are weld inspection, corrosion testing, small castings, forgings and delamination checking

Original: Sonatest/England

Quantity: 02 sets |

|

|

| |

|

|

| 2. Portable UT Flaw Detector USM 35X DAC LEMO |

|

|

|

Applications: Calculate surface distance, depth, & soundpath to the reflector; Curvature correction; Correct projected position in case of radial scan; Color Leg; Facilitate reflector positioning indicating the different legs with different colored backgrounds

Original: GESensing & Inspection Technologies/Germany

Quantity: 05 sets |

|

|

| |

|

|

|

3. Portable UT Flaw Detector – Epoch 4Plus/Epoch LT/Epoch LTC/

MG2-XT |

|

|

|

Applications: The Panametrics-NDT™ EPOCH 4PLUS / EPOCH LT/MG2-XT is anadvanced digital ultrasonic flaw detector featuring a multi-color LCD and a host of new features to meet challenging inspection requirements. It combines powerful flaw detection andmeasurement capabilities, extensive data storage, and the ability to transfer detailedinspection data to the PC via its high-speed USB port

Original: OlympusNDT-Panametrics/USA

Quantity: 08 sets |

|

|

| |

|

|

| 4. Cables, Probe and Block |

|

|

| |

|

|

| III. MT Equipments |

|

|

| |

|

|

| 1. MT Equipments – MT Yoke MP 2A |

|

|

|

Applications: Magnetic Inspection Yoke MP2A designed to perform magnetic particle inspections quickly and reliably

Original: Kyungdo/Korea

Quantity: 15 sets |

|

|

| |

|

|

| 2. UV Black light ZB100F |

|

|

| Applications: The ZB100F, designed for use with fluorescent dye penetrant and magnetic particle inspection processes, generates and emits ultra violet light with a wavelength of 365nanometers; the preferred wavelength for NDT inspection |

|

|

| |

|

|

| IV. MT Consumables |

|

|

| |

|

|

| 1. MP-35 (NABAKEM MP-35) |

|

|

|

¾ No offensive smell.

Bright color.

¾ Easy to remove.

¾ Fast drying. |

|

|

| |

|

|

| 2. SM-15 (NABAKEM SM-15) |

|

|

| Can be detected with the naked eye |

|

|

| |

|

|

| V. PT Consumables |

|

|

|

MEGA CHECK (Mega check Coloring Penetrant Detection

Agent for Crack Detection):

¾ Very fine detected.

¾ Non-corrosive agent.

¾ Easy to use.

¾ Can be sprayed at any direction(360) |

|

|

| |

|

|

| VI. Hardness Tester – MH320/TH130 |

|

|

|

Applications: Die cavity of molds; bearings and other parts, failure analysis of pressure vessel, steam generator and other equipmnets; heavy work piece; the installed machinery and permanently assembled parts; testing surface of a small hollow space; material identification in the warehouse of metallic materials; rapid testing in lare range and multi-measuring areas for large scale work piece

Original: China / Australia

Quantity: 02 sets

|

|

|

| |

|

|

| ADVANCED NDT EQUIPMENTS |

|

|

| |

|

|

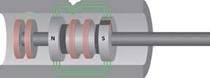

| 1. MultiScan 5800 for Tube Inspection |

|

|

|

Applications: Eddy current testing (ECT) is a noncontact method for the inspection of nonferromagnetic tubing. This technique is suitable for the detection and sizing of metaldiscontinuities such as corrosion, erosion, wear, pitting, baffle cuts, wall losses, and cracks in nonferrous materials

|

|

|

|

Remote field (RFT) is used for the inspection of ferromagnetic tubes, such as carbon steel and ferritic stainless steel. This inspection technique detects and sizes wall thinning caused by corrosion, erosion, wear, pitting, and baffle cuts. R/D Tech® remote field equipment has been used successfully on several applications: tube and shell heat exchangers, feedwater heaters, boiler tubes, and buried pipes.

Magnetic flux leakage (MFL) is a fast inspection technique, suitable for wall-loss measurement and detection of sharp defects, such as pitting, grooving, and circumferential cracks. MFL is effective for aluminum-finned carbon steel tubes, because the magnetic field is mostly unaffected by the presence of such fins

|

|

|

| The IRIS ultrasonic option is used for the inspection of a wide range of materials, including ferrous, nonferrous, and nonmetallic tubing. This technique allows detection and sizing of wall loss as the result of corrosion, erosion, wear, pitting, cracking, and baffle cuts. R/D Tech®digital IRIS inspection technology is used extensively as a backup technique for remote field,magnetic flux leakage, and eddy current inspections |

|

|

| |

|

|

| 2. Remote Visual Inspection (RVI) |

|

|

|

Applications:

The IPLEX MX supplies a slim ø4.4mm outer diameter tube with a short 15mm hard tip and asmall curvature radius for effortless insertion ease and convenient access to minute parts. It's especially effective for high-precision jobs in intricate spaces, such as inspecting small gas turbines and heat exchanger tubes

Original: Olympus/Japan

Quantity: 01 set |

|

|

| |

|

|